We're one of the most professional FA One-stop suppliers in China.Our main products including servo motor, planetary gearbox, inverter and PLC, HMI.Brands including Panasonic, Mitsubishi, Yaskawa, Delta, TECO, Sanyo Denki ,Scheider, Siemens , Omron and etc.; Shipping time: Within 3-5 working days after getting the payment. Payment way: T/T, L/C, PayPal, West Union, Alipay, Wechat and so on

Spec Detail

| Item | Specifications |

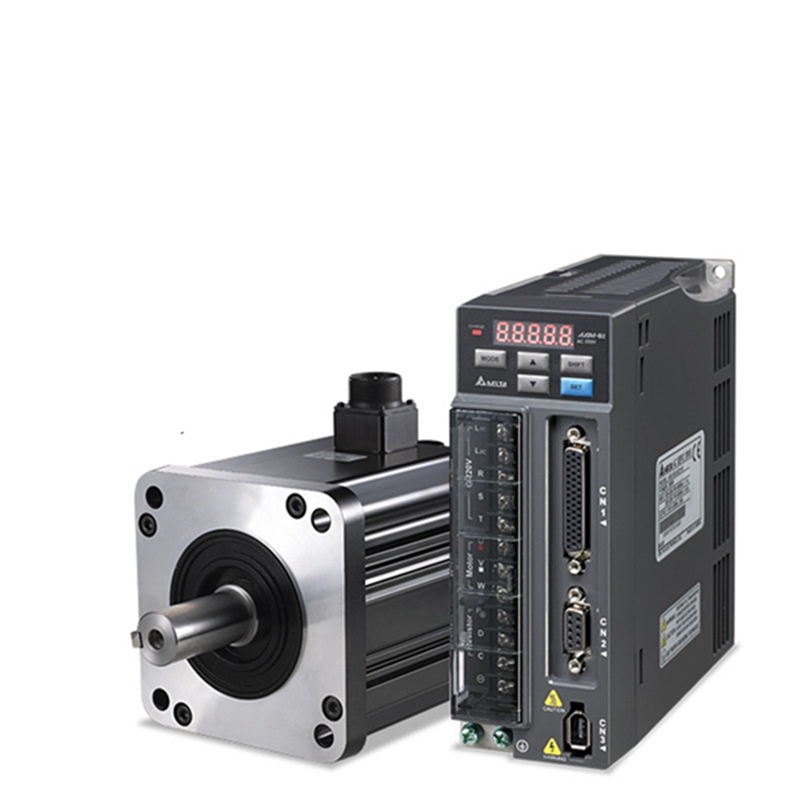

| Part number | ECMA-C10602RS |

| Product Name | Electronic Commutation AC Servo Motor |

| Servo Type | AC Servo |

| Corresponding Servo Motor | ASD-A2-0221-L, ASD-A2-0221-MASD-A2-0221-U, ASD-A2-0221-E |

| Rated Voltage | 220VAC |

| Encoder Type | Incremental type, 20-bit |

| Motor Frame Size | 60mm |

| Type of Shaft Diameter and Oil Seal | Keyway (with fixed screw holes), with brake, with oil seal |

| Standard Shaft Diameter | S=8m |

| Rated Power Output | 200W |

| Rated torque (N-m) | 0.64 |

| Max. torque (N-m) | 1.92 |

| Rated Speed | 3000 rpm |

| Max. speed | 5000 rpm |

| Rated current (A) | 1.55 A |

| Max. instantaneous current (A) | 4.65 A |

| Power rating (kW/s) | 22.4 |

| Rotor inertia (× 10-4kg.m2) | 0.19 |

| Mechanical constant (ms) | 0.75 |

| Torque constant-KT (N-m/A) | 0.41 |

| Voltage constant-KE (mV/(r/min)) | 16.0 |

| Armature resistance (Ohm) | 2.79 |

| Armature inductance (mH) | 12.07 |

| Electric constant (ms) | 4.30 |

| Insulation class | Class A (UL), Class B (CE) |

| Insulation resistance | > 100 M ohm , DC 500 V |

| Insulation strength | 1.8k Vac, 1 sec |

| Weight (kg) (with brake) | 1.5Kg |

| Radial max. loading (N) | 196 |

| Axial max. loading (N) | 68 |

| Power rating (kW/s) (with brake) | 21.3 |

| Rotor inertia (× 10-4kg.m2) (with brake) | 0.19 |

| Mechanical constant (ms) (with brake) | 0.85 |

| Brake holding torque Nt-m(min)] | 1.3 |

| Brake power consumption (at 20 °C) [W] | 6.5 |

| Brake release time [ms (Max)] | 10 |

| Brake pull-in time [ms (Max)] | 70 |

| Vibration grade (μm) | 15 |

| Vibration capacity | 2KG |

| IP Rating | IP65 |

Rubber & Plastics

Rubber and plastics are common materials used in our daily lives as well as in national defense and aerospace technology to vehicles, machinery, electronics, and buildings. As the global green economy and eco-awareness are rising, new materials, technology and applications are accelerating the development and transformation of the rubber & plastics industry.

Delta is dedicated to the rubber and plastics industry contributing years of experience in power, electronics, and industrial automation. Delta offers a broad range of products, such as heavy-load AC motor drives, PLCs, HMIs, temperature controllers, power meters and industrial power supplies, an all-electric injection molding machine solution (including control panels, specific controllers, AC servo drives & motors, and temperature controllers) and a hybrid energy-saving injection molding solution (including control panels, specific controllers, AC servo drives & motors, oil pumps and temperature controllers). Delta’s wide range of offerings fulfill the requirement for energy-saving, precise, high-speed and efficient system control for the rubber and plastic equipment.

Fluid Automation Systems

Fluid automation systems are mainly applied for controlling the complex processes of air-conditioning systems, air compressors, and water treatment plants. Replacing manual process management with an automated system achieves efficient and stable operations with distributed processing capabilities, constant control, and central monitoring.

Delta is dedicated in developing reliable and optimized automation products, such as PLCs, AC motor drives, servo drives and motors, HMIs, and temperature controllers. For high-end applications, Delta presents mid-range PLCs with excellent algorithms and stability. Adopting a modular design with various extension modules for system scalability, Delta’s mid-range PLC features integrated PLC programming software and an operation interface with multiple function blocks (FB). Delta also offers a variety of industrial Ethernet switches to connect different industrial networks for precise process monitoring. The highly efficient, stable, and reliable automation systems meet the requirements for a wide range of fluid system applications.

Woodworking Machinery

Traditional furniture manufacturing and processing relies heavily on inefficient and inconsistent manual work. Equipped with only a simple processing function, traditional woodworking machinery requires different machines for complex processes, such as side milling and engraving. The monotonous processing makes it difficult to meet market demand, and the woodworking machinery industry is seeking a more advanced solution.

To meet application demands, Delta presents its latest motion control solution for woodworking machinery. With the EtherCAT and DMCNET fieldbus supported PC-based and CNC controllers, Delta’s advanced woodworking machinery solution can be widely applied to automated labeling machines, routers with automatic conveyor systems, PTP routers, 5-sided drilling and boring machines, machining centers for woodworking, solid wood door machines and mortise & tenon Machines.