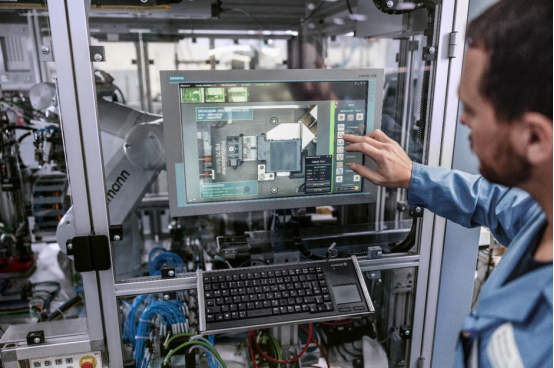

The human-machine interface at Siemens

The SIMATIC HMI (Human Machine Interface) is a key element in the company’s integrated industrial visualization solutions for monitoring machines and systems. It offers maximum engineering efficiency and comprehensive control using operating panels or PC-based software and hardware solutions. Due to increasing digitalization, HMI and SCADA solutions like SIMATIC HMI are crucial for the control of complex environments and lay the foundation for the integration of OT and IT.

Background information on the humanmachine interface at Siemens • The Siemens site in Fürth is the home of the HMI for Siemens. It’s home to the global development center for software and hardware for operating, monitoring, controlling, and optimizing production as well as the production of the associated HMI products.

• Megatrends like the shortage of skilled workers are influencing the production of tomorrow. Modern technologies are enabling a new level of productivity, and production is becoming increasingly software-defined.

• Siemens offers an innovative portfolio in the automation business, which includes the newly developed WinCC Unified visualization system based on native Web technologies. This system is fully scalable in terms of hardware and software, offers open interfaces and option packages for industryspecific applications, and employs the proven engineering of the TIA Portal.

• All application scenarios for HMI and supervisory control can be implemented in a single WinCC Unified-based system. Siemens offers the most technologically advanced and integrated system that includes PLC-based HMI solutions, a variety of unified HMI panels, and client-server solutions as an integration platform for factory-wide production systems.

• Beyond, Siemens HMIs focus on security and user-friendliness to facilitate people-centric production, which is already being implemented at the electronics plant in Fürth. Examples include secure login and authentication using biometric sensors, fast notifications for diagnostics and service using smartwatches, and micro-learning during the production process.

• The consistent further development of Siemens HMIs supports continuous digital transformation. Users now also benefit from linking options with Industrial Edge and additional applications that can be seamlessly integrated into an overall WinCC Unified system.

• Simatic Unified Air is the latest HMI application from Siemens that uses contactless communication and artificial intelligence to increase efficiency in machine operation: It permits the use of personal mobile devices like smartphones, smartwatches, and smart glasses for machine control using gesture and voice recognition. It also facilitates inspection work with the integration of augmented reality or VR glasses that display the machine status, show important instructions, and allow remote support in real time.

• This innovative contactless communication simplifies the operation of machines in many work environments: for example, when working in a protective suit in cleanrooms and chemical plants. Gloves would typically need to be removed in order to operate the control panel on the HMI panel: Voice or gesture control simplifies the process and increases efficiency by saving time.

• The Siemens automation portfolio is being continuously improved thanks to the use of artificial intelligence: o The Siemens Industrial Copilot for Engineering increases productivity by supporting automation engineers in creating code and diagnosing errors. This reduces the time and workload of engineering teams. o With Industrial Copilot for Operations, operators and maintenance technicians can interact with machines by leveraging the intelligence of existing documentation such as work instructions or manuals together with process and sensor data via IIoT and edge devices.

Post time: Oct-11-2025