We're one of the most professional FA One-stop suppliers in China.Our main products including servo motor, planetary gearbox, inverter and PLC, HMI.Brands including Panasonic, Mitsubishi, Yaskawa, Delta, TECO, Sanyo Denki ,Scheider, Siemens , Omron and etc.; Shipping time: Within 3-5 working days after getting the payment. Payment way: T/T, L/C, PayPal, West Union, Alipay, Wechat and so on

Technical specification

| Screen size: | 7" |

| Display type: | TFT colour LCD |

| Display dimensions: | w154 x h85.9mm |

| Graphical resolution: | 800 x 480 pixels |

| Power supply: | 24V d.c. |

| Interface: | RS422, RS232, Ethernet, USB and SD card |

| Overall dimensions: | w206 x h155 x d50mm |

| Weight: | 0.9kg |

Applications

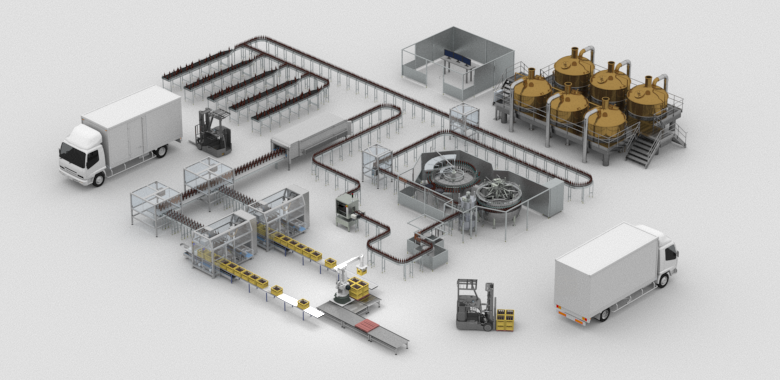

Food & Beverage

Brewery

Filling/CIP

Process to fill bottles and cans with end-product beverage. To improve productivity, accurate and quick filling/sealing are basic requirements. Mitsubishi Electric factory automation products realize accurate nozzle control in accordance with the container shape and the amount of filler, as well as reduce changeover time and ensure effective measures against the entry of foreign matter, thereby contributing to improved productivity.

Labeling

Process for printing letters such as expiration date and serial number, and then affixing product labels. Precision printing is necessary for food traceability (product tracing/ingredient tracing). Mitsubishi Electric factory automation products can ensure continuous quality by printing precisely and affixing product labels correctly in synchronization with high-speed conveyance systems, thereby reducing product loss.

Inspection

Eliminating defects and reducing downtime are basic requirements of automated systems, especially in the food and beverage industry where product quality is a top priority. Mitsubishi Electric offers a wide lineup of products capable of implementing and conducting inspections efficiently and at lower cost while maintaining the total quality of the manufactured product.